OUR CAPABILITIES

CNC Turned Parts

CNC Turned Parts are parts that are machined using a computer numerical control (CNC) lathe. This processing method mainly utilizes turning tools to perform turning on rotating workpieces, in order to achieve predetermined shapes and sizes. On the lathe, other tools such as drill bits, reamers, taps, dies, and knurling tools can also be used for further processing.

CNC Machined Parts

CNC Machined Parts are made by CNC Machined lathe which is very flexible and can adapt to the machining requirements of different shapes and sizes of parts by modifying the machining program. This enables CNC machine tools to process various complex parts without the need for machine tool replacement or tool adjustment

CNC Turned Components

CNC Turned Components can achieve high machining accuracy, generally reaching the accuracy level of IT11-IT7. The surface roughness Ra can reach 12.5-0.8um. CNC Turning is a method of cutting workpieces on a lathe through the rotational motion of the workpiece and the linear or curved motion of the tool.

Precision Turned Parts

The manufacturing process of Precision Turned Parts emphasizes high precision, and the dimensions and shapes of these parts are manufactured according to strict standards and tolerances to ensure accurate fit during assembly and use. They have a high surface finish and can meet various complex working conditions.

CNC Turned Parts Manufacturer

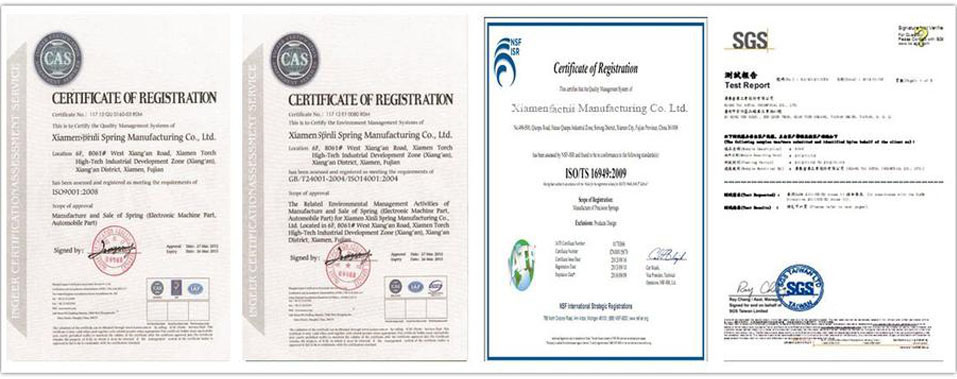

Turned.Parts is an enterprise specializing in the processing of Precision CNC Turned Parts, CNC Machined Parts, CNC Turned Components, precision screws, nuts and fasteners. we have a factory area of over 4000 square meters and we are located in the coastal city of Xiamen, only an hour’s drive from the port. We have over 20 years of experience in precision hardware machining production, have introduced various advanced production equipment and technologies, and have passed the quality management system certification ISO9001:2008 and environmental protection system ROHS certification.

We mainly produce 304,303 stainless steel, aluminum alloy, brass, iron and other materials, and have rich experience in customizing non-standard parts. The precision hardware produced by Turned.Parts are mainly used for LED lighting equipment, electrical equipment, bathroom heating, baby strollers, automotive parts, electronic appliances, medical equipment, toys, etc.

CNC Turned Parts

Our automatic turned parts lathe can achieve fully automatic processing, reduce labor costs, and improve production efficiency. More complex turning parts can be produced automatically using CNC machining machines with robotic arms, greatly reducing labor costs.

CNC Turned Parts is a high-precision and high-efficiency machine method that can perform precise turning of workpieces according to pre programmed instructions. Mainly using turning tools for turning rotating workpieces. In addition, the lathe can also be used in conjunction with drill bits, reamers, taps, dies, and knurling tools for corresponding processing. CNC lathe machining is mainly used for machining shafts, discs, sleeves, and other workpieces with rotating surfaces.

More Services for CNC machining

We also provide follow-up processing for CNC machining, such as tapping, drilling, etc., which are crucial for improving the quality and accuracy of the workpiece.

1. Tapping (tapping): Tapping is a mechanical machining method that produces internal threads on a workpiece. According to the thread specifications, pre drill bottom holes with a diameter typically 0.1 to 0.2 millimeters larger than the minor diameter of the thread. Install the tap on the tapping machine and machine the thread on the bottom hole through the rotation and feed of the tap.

2. Drilling: Drilling is the process of machining circular holes on a workpiece. Fix the workpiece on the drilling machine workbench to ensure that the surface of the workpiece is flat and accurately positioned. Start the drilling machine, rotate the drill bit at a certain speed and feed rate, and feed it downwards to form a hole.

OUR SERVICES

Quality Service

We purchase a lot of equipment of 2D imaging instrument, industrial electron microscope,etc., continue to work hard to ensure product quality.

Consulting Service

Feel free to consult us at any time if you have any product design related issues with your CNC Turned Parts, CNC Machined Parts.

Project Service

Our technical personnel will provide you with full support throughout the entire project, from product design, to sampling, to mass production later on.

One-Stop Service

We provide precision turned parts, machining parts, stamping parts, and related assembly to enable you to efficiently manage suppliers.

Products Showcase

Custom CNC Turned Parts For Auto

The Machining Processing Cost of CNC Turned Parts

How do CNC Turned Parts Machining Service Work

OUR CERTIFICATES