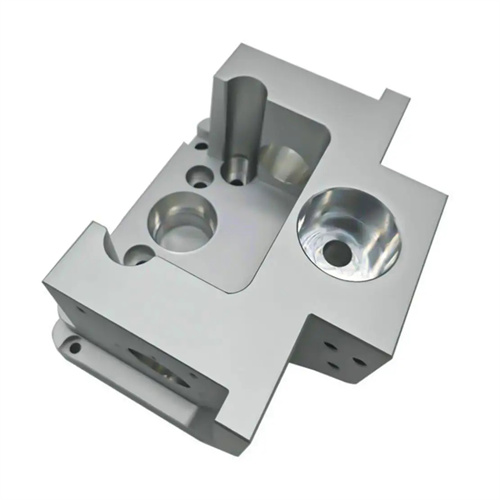

CNC machined parts also known as computer-controlled machining parts, are components that are processed with high precision and efficiency using CNC machine tools. CNC machining technology is a technology that uses computer-controlled machine tools to process parts. It automatically controls the machine tool to perform various cutting, drilling, milling and other machining operations based on pre written programs. The core of CNC machining technology is digital control, which converts machining instructions into code that the machine tool can understand through computer software, thereby controlling the motion and machining process of the machine tool.

CNC Machined Parts are widely used in the following fields:

Aerospace field: used to manufacture engine parts, fuselage components, etc. for aircraft, satellites, and other aerospace spacecraft.

Automotive manufacturing field: used for manufacturing automotive parts, frames, body panels, etc.

Mold processing: CNC machining is an important technical means of mold processing, which can manufacture high-precision and complex shaped molds.

Precision machinery: fields that require high-precision processing, such as medical devices and precision instruments.

CNC Machined Parts have the following characteristics:

High precision: Through computer control, extremely high machining accuracy can be achieved.

High efficiency: With a high degree of automation, it can continuously process CNC machined parts, improving production efficiency.

Strong flexibility: By modifying the machining program, it can quickly adapt to the machining needs of different CNC machined parts.

Strong adaptability: It can process CNC machined parts of various materials and shapes, especially complex shaped parts.

The CNC Machined Parts machining process includes various machining methods, such as:

Tool centralized sorting method: Divide the process based on the tools used, reducing the inconvenience and positioning errors caused by tool changing.

Rough and precision machining sequencing method: CNC machined parts are first subjected to rough or semi precision machining, followed by precision machining to improve machining accuracy and finished product qualification rate.

Sorting method based on processing parts: first process the CNC machined parts plane and parts with lower precision requirements, and then process complex and high precision parts.

As Chinese manufacturers of custom CNC machined parts, we stand at the intersection of rich industrial heritage and cutting – edge innovation, ready to serve the global market with our unparalleled expertise and commitment to excellence. In a world where precision, efficiency, and customization are highly valued, we have carved out a niche for ourselves by leveraging our unique strengths and the vibrant manufacturing ecosystem in China.

Our manufacturing facilities are equipped with the latest generation of CNC machining equipment, sourced from leading global and domestic suppliers. This state – of – the – art machinery, combined with our advanced computer – aided design (CAD) and computer – aided manufacturing (CAM) systems, empowers us to handle a vast array of custom machining projects. Whether our clients require simple components or complex parts with intricate geometries, we have the capabilities to bring their designs to life with meticulous precision. We can work with a diverse range of materials, from common metals like aluminum, stainless steel, and brass to high – performance engineering plastics and exotic alloys. This material versatility allows us to cater to the specific needs of industries such as aerospace, automotive, medical, electronics, and more.

What truly sets us apart is our unwavering focus on customization. We understand that each project is unique, and we take the time to listen closely to our clients’ requirements. Our experienced engineering team collaborates closely with clients from the initial design concept stage, offering valuable insights and suggestions to optimize the design for manufacturability. Through seamless communication and iterative feedback loops, we ensure that the final custom CNC machined parts not only meet but exceed our clients’ expectations. We are not just manufacturers; we are partners in innovation, helping our clients turn their ideas into tangible, high – quality products.

Quality is the cornerstone of our manufacturing philosophy. We have implemented a comprehensive quality control system that adheres to international standards such as ISO 9001. Every step of the manufacturing process, from raw material inspection to the final product check, is rigorously monitored. Our skilled quality control technicians use advanced measuring instruments, including coordinate measuring machines (CMMs) and optical comparators, to verify the dimensional accuracy and surface finish of each part. By maintaining strict quality control, we ensure that our custom CNC machined parts are reliable, durable, and perform flawlessly in their intended applications.

In addition to quality and customization, we also pride ourselves on our competitive pricing and efficient production lead times. Thanks to China’s well – developed manufacturing supply chain and our streamlined production processes, we can offer cost – effective solutions without compromising on quality. Our optimized production planning and scheduling systems enable us to meet tight deadlines, providing our clients with quick turnaround times. Whether it’s a small – batch production for prototyping or a large – scale order for mass production, we have the capacity and flexibility to handle it efficiently.

As Chinese manufacturers, we also embrace sustainable manufacturing practices. We are committed to reducing our environmental impact by implementing energy – saving measures, recycling materials, and minimizing waste generation. By choosing us as their custom CNC machined parts manufacturer, clients can be confident that they are partnering with a company that values both quality and environmental responsibility.

In conclusion, as Chinese manufacturers of custom CNC machined parts, we are dedicated to providing our clients with world – class products and services. With our advanced technology, focus on customization, uncompromising quality, competitive pricing, and sustainable practices, we are well – positioned to meet the evolving needs of the global manufacturing industry and contribute to the success of our clients’ projects.