In the rapidly evolving electronic products industry, where miniaturization, high performance, and precision are the driving forces, CNC machined parts have become indispensable in shaping the future of electronics. These precisely crafted components, produced through advanced computer – numerical – control machining, empower us to meet the ever – increasing demands for intricate designs, tight tolerances, and reliable functionality. From the tiniest components within a smartphone to the complex structures of high – end servers, CNC machined parts play a crucial role in every stage of electronic product development, ensuring that our products are not only innovative but also durable and user – friendly.

1. CNC Machined Parts: Fabrication of Precision Electronic Connectors

One of the primary applications of CNC machined parts in electronic products is the fabrication of precision electronic connectors. We rely on CNC machining to create connectors that can establish reliable electrical connections in a compact and efficient manner.

Using CNC machining, we can shape conductive materials such as copper and gold – plated alloys into highly intricate connector designs. The extreme precision of CNC machines allows us to produce connectors with pin pitches as small as a few tenths of a millimeter, which is essential for the miniaturization of modern electronics. For example, in high – speed data transfer devices like USB – C connectors and high – density board – to – board connectors, CNC – machined parts ensure that the contacts are perfectly aligned and have consistent surface finishes. This not only reduces signal loss and interference but also increases the durability of the connectors, enabling them to withstand repeated plugging and unplugging. The ability to customize connector shapes and sizes through CNC machining also allows us to meet the specific requirements of different electronic devices, ensuring seamless integration of components.

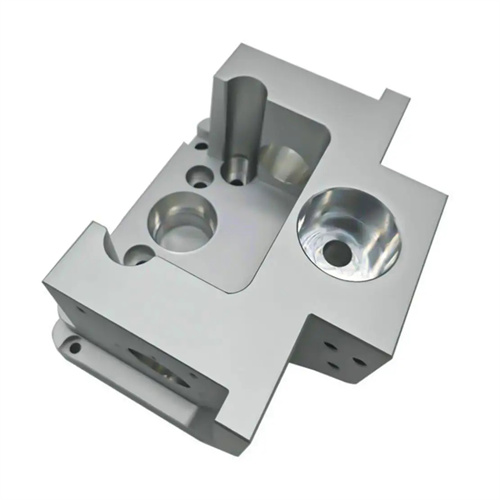

2. CNC Machined Parts: Production of Electronic Device Enclosures

The enclosure of an electronic device serves as both a protective barrier and a design element, and CNC machined parts are used to produce high – quality enclosures that meet strict standards.

For smartphones and tablets, CNC – machined aluminum or magnesium alloy enclosures offer a perfect balance of strength, lightweight, and aesthetic appeal. The precision of CNC machining enables us to create enclosures with smooth curves, precise cutouts for ports and buttons, and seamless fits for internal components. In laptops, CNC – machined metal frames provide structural support, protecting the delicate motherboards and other internal parts from physical damage. Additionally, the high – quality surface finish achieved through CNC machining, whether it’s a matte, brushed, or polished look, enhances the overall user experience and brand image of the electronic products. The tight tolerances ensured by CNC machining also allow for the integration of advanced features such as wireless charging coils and antennas within the enclosures without compromising on functionality or signal quality.

3. CNC Machined Parts: Creation of Heat Sinks for Electronics

With the increasing performance of electronic components, effective heat dissipation has become crucial, and CNC machined parts play a vital role in creating efficient heat sinks.

We utilize CNC machining to shape heat – conducting materials like aluminum and copper into complex heat sink geometries. The high – precision cutting and milling capabilities of CNC machines enable us to produce heat sinks with densely packed fins and optimized airflow channels. For example, in gaming laptops and high – performance desktop computers, CNC – machined heat sinks with micro – fin structures can significantly increase the surface area for heat transfer, effectively dissipating the heat generated by powerful processors and graphics cards. The ability to customize the shape and size of heat sinks through CNC machining allows us to fit them precisely within the limited space of electronic devices, ensuring optimal cooling performance while maintaining a compact form factor.

4. CNC Machined Parts: Assembly of Electronic Product Accessories

Electronic products often come with various accessories, and CNC machined parts are used to create components that enhance the functionality and usability of these accessories.

For smartwatch bands, CNC – machined metal clasps and connectors provide a secure and stylish fastening mechanism. The precision machining ensures that the parts fit together seamlessly, allowing for easy attachment and detachment of the bands. In tablet stands and laptop docks, CNC – machined joints and brackets offer smooth and stable adjustments, enabling users to find the most comfortable viewing angles. Additionally, for external storage devices like hard drive enclosures, CNC – machined parts are used to create shock – absorbing structures and secure mounting points, protecting the internal storage components during transportation and use. The high – quality and precise nature of CNC – machined accessory parts contribute to the overall quality and user satisfaction of electronic products.

5. CNC Machined Parts: Facilitating Maintenance and Upgrades of Electronic Products

The use of CNC machined parts in electronic products also greatly facilitates maintenance and upgrades, which are essential in the fast – paced electronics industry.

When a component in an electronic device needs to be replaced, the standardized and precisely – machined parts can be easily removed and swapped out. The modular design enabled by CNC machining allows for quick access to internal components, reducing repair time and costs. As technology advances, we can use CNC machining to produce upgraded parts with enhanced features. For example, when upgrading the cooling system of a server, CNC – machined replacement heat sinks with improved thermal conductivity can be installed. The ability to customize and produce parts on – demand through CNC machining ensures that our electronic products can adapt to new technological requirements, extending their lifespan and keeping them competitive in the market.