In the ever – evolving landscape of household appliances, where consumer demands for reliability, efficiency, and user – friendliness are constantly on the rise, CNC machined parts have emerged as a game – changer in our manufacturing processes. These precisely crafted components, produced through advanced computer – numerical – control machining, empower us to create appliances that not only meet but exceed the expectations of modern households. From enhancing the structural integrity of large – scale appliances to improving the functionality of small – scale devices, CNC machined parts play a crucial role in every aspect of household appliance production, enabling us to deliver high – quality products that stand the test of daily use.

1. CNC Machined Parts: Reinforcing the Structural Integrity of Large – Scale Appliances

One of the primary applications of CNC machined parts in household appliances is in reinforcing the structural integrity of large – scale devices such as refrigerators, washing machines, and ovens. We rely on CNC machining to produce components that can withstand the rigors of daily operation and provide long – lasting stability.

For refrigerators, CNC – machined metal brackets and frames are used to support the weight of the doors, shelves, and cooling systems. The high – precision cutting and shaping capabilities of CNC machines ensure that these components fit together perfectly, minimizing any potential wobbling or misalignment. In washing machines, CNC – machined parts are crucial for the assembly of the drum support structures and motor mounts. These parts are designed to endure the vibrations and mechanical stresses generated during the wash and spin cycles, preventing premature wear and tear. Similarly, in ovens, CNC – machined racks and heating element supports are crafted with exacting precision to ensure even heat distribution and safe operation. By using CNC machined parts, we can enhance the overall durability of large – scale appliances, providing consumers with reliable products that last for years.

2. CNC Machined Parts: Enhancing the Performance of Small – Scale Appliances

Small – scale household appliances, such as blenders, coffee makers, and hair dryers, also benefit significantly from the use of CNC machined parts. We utilize CNC machining to create components that can improve the functionality and performance of these devices.

In blenders, CNC – machined blades are designed with precise angles and cutting edges to ensure efficient blending and chopping. The high – precision manufacturing process allows for consistent blade thickness and shape, resulting in better performance and longer blade life. For coffee makers, CNC – machined parts are used in the brewing mechanisms, such as the water pumps and filter holders. These parts are crafted to exact specifications, ensuring a consistent and high – quality coffee extraction. In hair dryers, CNC – machined nozzles and air vents are designed to direct airflow precisely, enabling users to style their hair more effectively. The use of CNC machined parts in small – scale appliances not only enhances their performance but also improves the overall user experience.

3. CNC Machined Parts: Optimizing the Heat Dissipation of Electrical Appliances

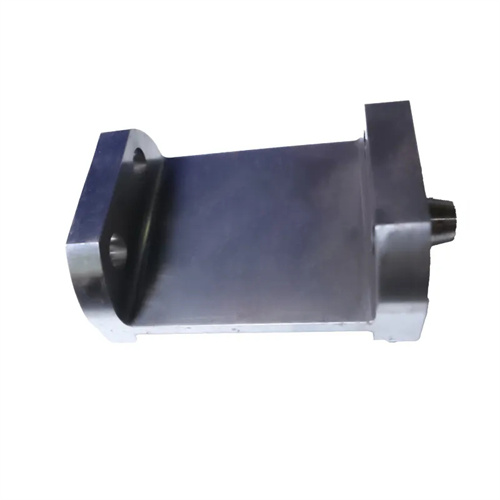

Many household appliances, especially those with electrical components, generate heat during operation, and effective heat dissipation is essential for their reliable performance and longevity. CNC machined parts play a vital role in optimizing the heat dissipation of these appliances.

For microwave ovens and toaster ovens, CNC – machined heat sinks are used to dissipate the heat generated by the heating elements and electrical circuits. These heat sinks are designed with complex fin patterns and precise geometries to maximize the surface area for heat transfer. In computer – controlled appliances, such as smart thermostats and washing machines with digital controls, CNC – machined heat – conducting components are used to manage the heat generated by the microprocessors and other electronic components. By using CNC machining, we can create heat – dissipation solutions that are tailored to the specific requirements of each appliance, ensuring that they operate at optimal temperatures and have an extended lifespan.

4. CNC Machined Parts: Facilitating the Assembly of Appliance Accessories

Household appliances often come with various accessories, and CNC machined parts are used to facilitate the assembly of these components, enhancing the functionality and versatility of the appliances.

For refrigerators, CNC – machined shelf supports and drawer slides are used to ensure smooth and easy operation. These parts are manufactured with high precision to provide a secure fit and prevent any rattling or movement during use. In vacuum cleaners, CNC – machined hose connectors and brush attachments are designed to fit snugly, ensuring efficient suction and easy maneuverability. For kitchen appliances, such as mixers and food processors, CNC – machined bowl locks and blade adapters are used to ensure safe and secure operation. The use of CNC machined parts in the assembly of appliance accessories not only improves the functionality of the appliances but also makes them more user – friendly and convenient.

5. CNC Machined Parts: Simplifying the Maintenance and Upgrades of Household Appliances

The use of CNC machined parts in household appliances also simplifies the maintenance and upgrade processes, which are essential for keeping these products in optimal working condition and adapting to changing consumer needs.

When a component in a household appliance needs to be replaced or repaired, the standardized and precisely – machined nature of CNC parts allows for easy removal and installation. The modular design enabled by CNC machining means that technicians can quickly identify and access the faulty component, reducing downtime and repair costs. In addition, as technology advances, we can use CNC machining to produce upgraded parts with enhanced features and performance. For example, when upgrading the control system of a dishwasher, we can manufacture new CNC – machined parts with improved sensors and actuators, enabling the dishwasher to operate more efficiently and effectively. The flexibility and precision of CNC machining ensure that we can keep our household appliances up – to – date and provide consumers with products that meet their evolving needs.