In the fast – paced and technology – driven electronic products industry, precision turned parts have emerged as indispensable assets in our manufacturing processes. Leveraging the high – accuracy and versatility of precision turning technology, we are able to produce components that meet the stringent demands of modern electronics. These parts play a crucial role in enhancing the performance, durability, and miniaturization of a wide range of electronic devices, from smartphones and laptops to advanced data center equipment. By integrating precision turned parts into our designs, we can ensure that our electronic products stand out in the market with superior quality and functionality.

1. Precision Turned Parts: Fabrication of High – Precision Electronic Connectors

One of the primary applications of precision turned parts in electronic products is the fabrication of high – precision electronic connectors. We rely on precision turning to create connectors that enable stable and efficient electrical and signal connections in increasingly complex electronic systems.

Using precision turning machines, we shape conductive materials such as copper, gold – plated alloys, and silver – plated metals into intricate connector designs. The high – precision machining process allows us to produce parts with extremely tight tolerances, ensuring a perfect fit for circuit boards, cables, and other electronic components. For example, in high – speed data transfer interfaces like USB 4.0, Thunderbolt 4, and HDMI 2.1, precision turned connectors are essential for maintaining signal integrity. The precisely machined pins and sockets minimize electrical resistance and interference, enabling data transfer rates of up to 40 Gbps or even higher. In addition, for wireless charging modules in smartphones and other devices, precision turned connectors ensure a reliable and efficient power transfer, eliminating the need for traditional wired connections.

2. Precision Turned Parts: Production of Heat – Dissipating Components

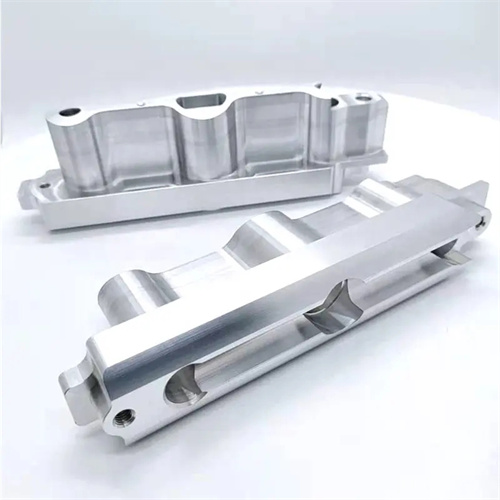

With the continuous increase in the power density of electronic components, effective heat dissipation has become a critical factor in ensuring the performance and lifespan of electronic products. Precision turned parts are used to create heat – dissipating components with optimized designs.

We utilize precision turning to shape heat – conducting materials, mainly aluminum and copper, into heat sinks and cooling fins with precise geometries. The high – precision machining allows us to produce components with thin and densely packed fins, maximizing the surface area for heat transfer. In high – performance gaming laptops and desktop computers, precision turned heat sinks play a vital role in keeping the CPU and GPU temperatures within safe limits. The smooth surfaces of these heat – dissipating parts reduce air resistance, facilitating better airflow and enhancing the overall heat – dissipation efficiency. Moreover, for server racks in data centers, precision turned heat – conducting components are customized to fit the specific heat – generating patterns of various electronic modules, ensuring stable operation even under heavy workloads.

3. Precision Turned Parts: Creation of Structural Elements for Electronic Devices

The structural integrity of electronic devices is crucial for protecting internal components and ensuring user safety, and precision turned parts are key to producing high – quality structural elements.

For smartphones, tablets, and wearables, precision turned parts are used to create frames, housings, and support structures. The precision of turning technology ensures that these components fit together seamlessly, providing a sturdy and durable enclosure for the delicate internal electronics. For example, the aluminum frames of high – end smartphones are often manufactured using precision turning, which allows for the creation of thin – walled structures with complex geometries. These frames not only provide structural support but also contribute to the aesthetic appeal of the devices. In addition, precision turned parts are used to produce mounting brackets, screws, and other fasteners for electronic devices, ensuring a secure and stable assembly that can withstand the rigors of daily use and transportation.

4. Precision Turned Parts: Assembly of Electronic Device Accessories

Electronic devices often come with various accessories, and precision turned parts are used to create these components with high precision and quality.

For smartwatch bands, precision turned metal clasps and connectors provide a secure and stylish fastening mechanism. The precision machining of these components ensures a perfect fit, allowing for easy attachment and detachment of the bands. In laptop accessories, such as external hard drive enclosures, cooling pads, and docking stations, precision turned parts are used to create structural parts, heat – dissipating elements, and connectors. These components are designed with precise dimensions and interfaces, ensuring seamless integration with the main devices. Additionally, precision turned parts can be used to create custom – designed accessories, such as phone grips, camera mounts, and tablet stands, which enhance the functionality and usability of electronic devices while adding a touch of personalization.

5. Precision Turned Parts: Facilitating Maintenance and Upgrades of Electronic Products

The use of precision turned parts in electronic products also greatly facilitates maintenance and upgrades, which are essential for keeping the products up – to – date and in optimal working condition.

When a component in an electronic product needs to be replaced or repaired, the standardized and precisely – machined nature of precision turned parts allows for easy identification and installation. The modular design enabled by precision turning simplifies access to internal components, reducing downtime and maintenance costs. As technology advances, we can use precision turning to produce upgraded parts with enhanced features and performance. For example, when upgrading the cooling system of a high – end gaming PC, we can manufacture new precision turned heat sinks with improved thermal conductivity and more efficient fin designs. When enhancing the connectivity of a tablet, we can produce new precision turned connectors with faster data transfer capabilities. The flexibility and precision of precision turned parts ensure that our electronic products can adapt to changing technological requirements and continue to meet the evolving needs of consumers.