In the dynamic and competitive sports goods industry, where performance, safety, and innovation are highly prized, CNC machined parts have become an essential element in our manufacturing processes. Leveraging the precision and versatility of computer – numerical – control machining, we are able to produce components that meet the rigorous demands of modern sports. These parts play a crucial role in enhancing the functionality, durability, and user experience of a wide range of sports equipment, from high – end professional gear to recreational sports products. By integrating CNC machined parts into our designs, we can create sports goods that not only help athletes excel but also provide enthusiasts with reliable and enjoyable equipment.

1. CNC Machined Parts: Enhancing the Performance of Fitness Equipment

One of the primary applications of CNC machined parts in sports goods is in enhancing the performance of fitness equipment. We rely on CNC machining to create components that can withstand intense use and provide a smooth, reliable workout experience.

For treadmills, CNC – machined parts are used to produce the frame components, such as the side rails and support brackets. The high – precision machining ensures that these parts fit together perfectly, providing a stable and sturdy base for the treadmill. This stability is crucial for preventing vibrations and ensuring a safe running surface. In weightlifting machines, CNC – machined pulleys and cables are designed with exacting precision to ensure smooth and consistent resistance during workouts. The use of CNC machining also allows for the creation of custom – designed weight plates, which can be tailored to the specific needs of athletes and fitness enthusiasts. These weight plates are not only more aesthetically pleasing but also offer better balance and grip, enhancing the overall performance of the weightlifting equipment.

2. CNC Machined Parts: Optimizing the Design of Bicycles

Bicycles require components that are both lightweight and strong, and CNC machined parts are ideal for achieving this balance. We utilize CNC machining to produce various bicycle components, from frames to drivetrain parts.

CNC – machined bicycle frames are often made from materials like aluminum alloy or titanium. The precision of CNC machining allows for the creation of complex tube shapes and thin – walled structures, reducing the weight of the frame without sacrificing strength. This results in bicycles that are not only easier to handle but also more efficient in terms of energy transfer. In addition, CNC – machined parts are used for the production of bicycle components such as cranksets, handlebars, and stems. These parts are designed with precise tolerances to ensure a perfect fit and smooth operation, enhancing the overall performance and ride quality of the bicycle. The ability to customize these components through CNC machining also allows cyclists to personalize their bikes according to their preferences and riding styles.

3. CNC Machined Parts: Ensuring Safety in Protective Gear

Protective gear is essential for safeguarding athletes from injuries, and CNC machined parts play a vital role in ensuring the safety and reliability of such equipment.

In football helmets, CNC – machined parts are used to create the internal frames and adjustment mechanisms. These parts are manufactured with high precision to ensure a snug and comfortable fit for players. The use of CNC machining also allows for the production of ventilation holes and channels, which help to keep players cool during games. In hockey pads, CNC – machined buckles and straps are designed to provide a secure and adjustable fit, ensuring that the pads stay in place during intense physical activity. The precision of CNC machining ensures that these components are strong enough to withstand the impact of collisions while still being easy to use and adjust. By using CNC machined parts in protective gear, we can provide athletes with reliable equipment that offers maximum protection.

4. CNC Machined Parts: Assembling Sports Facility Equipment

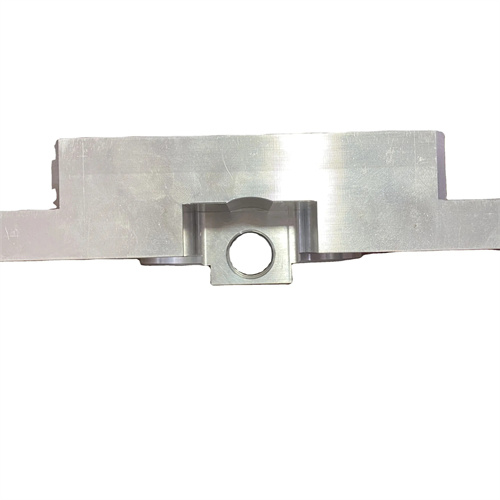

Sports facilities, such as stadiums, gyms, and swimming pools, rely on a variety of equipment, and CNC machined parts are used to assemble and maintain this equipment.

For basketball hoops, CNC – machined parts are used to produce the backboard frames, rim assemblies, and support structures. The high – precision machining ensures that these parts are strong enough to withstand the force of powerful dunks and rebounds. In swimming pools, CNC – machined ladders, handrails, and diving board components are designed to be corrosion – resistant and durable, ensuring the safety of swimmers. The use of CNC machining also allows for the creation of custom – designed sports facility equipment, which can be tailored to the specific needs and requirements of different sports venues. This ensures that the equipment not only functions properly but also meets the aesthetic and functional expectations of the facility.

5. CNC Machined Parts: Facilitating Maintenance and Upgrades of Sports Equipment

The use of CNC machined parts in sports goods also greatly facilitates maintenance and upgrades, which are essential for keeping the equipment in optimal condition and adapting to changing needs.

When a component of sports equipment needs to be replaced or repaired, the standardized and precisely – machined nature of CNC parts allows for easy removal and installation. This modular design, enabled by CNC machining, reduces downtime and maintenance costs. For example, if a pedal on a bicycle becomes worn out, a CNC – machined replacement pedal can be quickly installed, ensuring that the bicycle is back in use in no time. In addition, as sports technology advances, we can use CNC machining to produce upgraded parts with enhanced features and performance. For instance, in fitness equipment, we can manufacture new CNC – machined components that offer improved resistance levels or advanced digital monitoring capabilities. The flexibility and precision of CNC machining ensure that we can keep our sports equipment up – to – date and provide users with the best possible experience.