Turning of eccentric sleeves at both ends of cast iron

Cast iron eccentric sleeves are key components for achieving eccentric motion in mechanical transmissions. The inner and outer axis of the sleeves at each end have a certain eccentricity (typically 1-10mm). Machining accuracy directly impacts the smoothness of the mechanism’s motion and transmission efficiency. Due to the brittleness and wear resistance of cast iron, and the high centrifugal forces generated by the eccentric structure during machining, the turning process is prone to vibration, excessive tool wear, and excessive eccentricity. Therefore, a targeted machining plan is required, considering various aspects, including clamping method, tool selection, cutting parameters, and precision control.

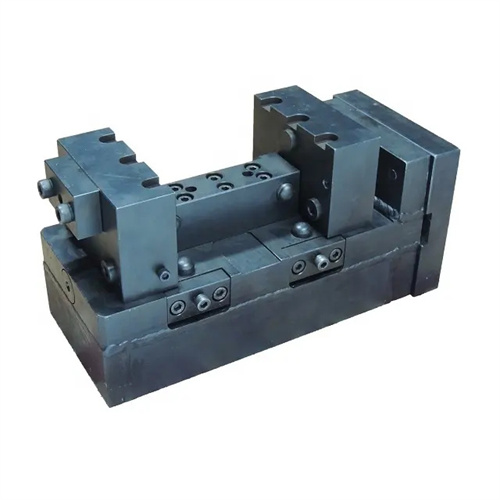

Choosing the right clamping method is essential for ensuring eccentric sleeve machining accuracy. For short eccentric sleeves less than 100mm in length, a three-jaw chuck with shims can be used. By inserting a copper shim with a thickness equal to the eccentricity between the chuck jaws and the workpiece’s outer diameter, the workpiece axis is offset to the desired eccentric position. This method is simple to operate, but eccentricity accuracy is significantly affected by shim thickness tolerances. It is therefore suitable for applications where eccentricity accuracy requirements are low (±0.05mm). For eccentric sleeves longer than 100mm or where high eccentricity accuracy requirements (±0.01mm) are required, a double-thimble clamping method with an eccentric sleeve is required. A center hole matching the eccentricity is machined at each end of the workpiece. The eccentric sleeve is then used to align the center hole axis with the spindle axis to the desired eccentricity. This ensures machining stability while allowing precise control of the eccentricity through adjustment of the eccentric sleeve.

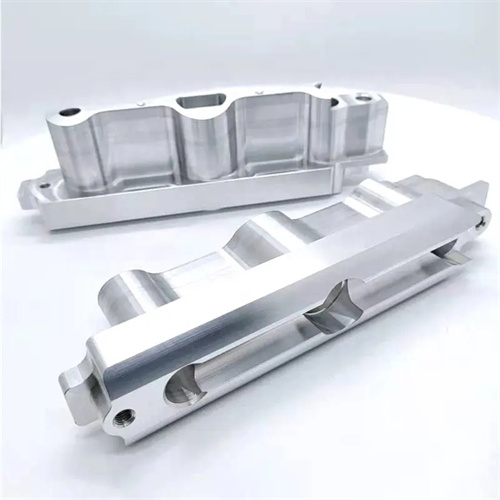

The main task of the rough turning stage is to remove most of the machining allowance and lay a good precision foundation for finish turning. When rough turning the outer circle, due to the large centrifugal force generated by the eccentric structure, the spindle speed needs to be appropriately reduced, generally to 300-500r/min, and a large feed rate (0.3-0.5mm/r) and cutting depth (2-3mm) are used at the same time to quickly remove excess material. When rough turning the inner holes at both ends, the inner hole at one end should be machined to 90% of the design size first. Then, using this inner hole as a reference, the inner hole at the other end is machined through the mandrel positioning and clamping to ensure that the coaxiality error of the inner holes at both ends does not exceed 0.03mm. For eccentric sleeves with uneven wall thickness, aging treatment (artificial aging: 200-250℃ for 4-6 hours) is required after rough turning to eliminate processing stress and avoid deformation during subsequent processing.

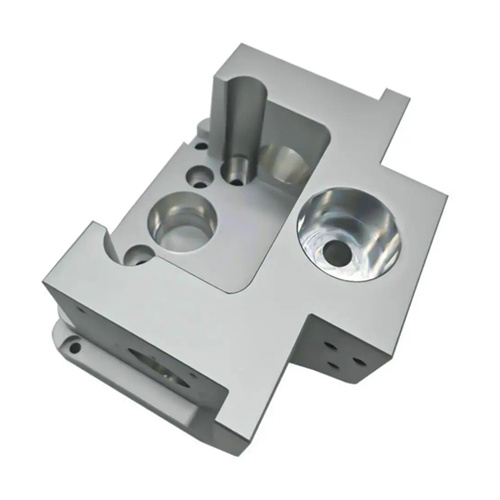

The focus of the finish turning phase is ensuring eccentricity accuracy, surface roughness, and form and position tolerances. When finish turning the external diameter, the spindle speed should be increased to 800-1000 rpm, with a smaller feed rate (0.1-0.15 mm/r) and depth of cut (0.1-0.3 mm). Coated carbide tools (such as TiAlN-coated YT15) should be used to leverage the coating’s high wear resistance to reduce tool wear, ensuring the external diameter surface roughness is within Ra1.6μm. When finish turning the internal hole, a floating boring tool or reamer should be used, with the tool’s automatic compensation function eliminating clamping errors and ensuring H7 dimensional accuracy of the internal hole. To control eccentricity accuracy, multiple measurements are required during the finish turning process. This can be achieved by mounting a dial indicator on the tool holder. Using the machined external diameter as a reference, rotate the spindle one full revolution and read the indicator’s maximum and minimum readings. Half the difference is the actual eccentricity, which can be gradually corrected to the designed value by adjusting the tool position.

Targeted process measures are required for turning eccentric sleeves with special structures. For composite eccentric sleeves with different eccentric distances at both ends, they need to be processed in stages. First, the eccentric structure at one end is processed, and then the eccentric position of the other end is positioned by a special fixture. Precision positioning pins need to be set on the fixture, and the position accuracy error should not exceed 0.005mm. For eccentric sleeves with keyways or planes, milling should be carried out after turning is completed to avoid deformation of the workpiece caused by milling force, which affects the eccentricity accuracy. During the processing, attention should be paid to the handling of cast iron chips. Since cast iron chips are in the form of fragments and can easily scratch the processed surface, high-pressure cutting fluid (flow rate ≥ 20L/min) should be used to flush away the chips in time, and a chip guard should be installed on the tool holder to prevent chip accumulation.

Final inspection and error analysis are the last steps to ensure the quality of the eccentric sleeve. An eccentricometer or a three-coordinate measuring machine is required to detect the eccentricity of the inner holes at both ends. The measurement accuracy should reach 0.001mm to ensure that it meets the design requirements. At the same time, it is necessary to check the coaxiality of the outer circle and the inner hole, the perpendicularity of the end face and the axis, and other form and position tolerances. If any deviation is found, the cause should be analyzed and compensation measures should be taken. For example, if the eccentricity error is caused by deformation during clamping, it can be eliminated by adjusting the top pressure or adding auxiliary support; if the size deviation is caused by tool wear, the tool must be replaced and re-calibrated in time. Through strict inspection and continuous process optimization, the processing quality of the eccentric sleeves at both ends of the cast iron can be ensured to be stable and reliable, meeting the use requirements of mechanical equipment.