There are significant differences between CNC machined parts and castings in multiple aspects. The following is a comparison and distinction between these two:

Processing principle:

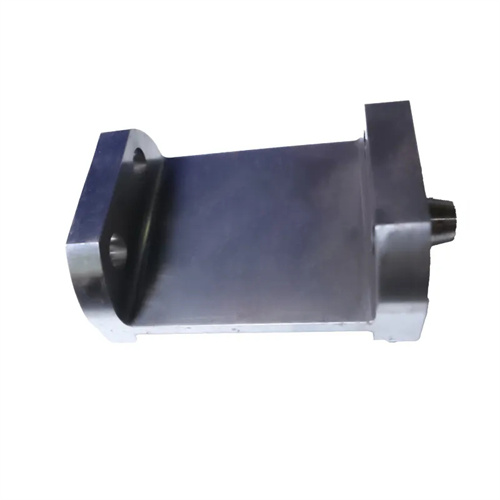

CNC Machined Parts: Using computer programs to control machine tools for processing, removing materials through cutting, drilling, milling, and other methods to achieve the desired shape and size of parts.

Casting: A part that is formed by pouring molten metal into a pre designed mold and allowing the metal to cool and solidify to obtain the desired shape.

Accuracy and tolerance:

CNC Machined Parts: With extremely high machining accuracy and tolerance control ability, it can produce high-precision and high-quality parts.

Casting parts: Although casting technology is constantly improving, its accuracy and tolerance control ability are relatively weak compared to CNC machining, especially for parts with complex shapes and sizes.

Material adaptability:

CNC Machined Parts: Suitable for processing various materials, including metal, plastic, wood, etc.

Casting parts: mainly suitable for the manufacturing of metal materials, especially large and complex metal parts.

Production efficiency:

CNC Machined Parts: Once the machine tool is programmed and set up, continuous automated processing can be carried out, resulting in high production efficiency.

Casting parts: The casting process is relatively complex, including multiple links such as mold design, manufacturing, melting, pouring, etc., and the production efficiency is relatively low.

Flexibility:

CNC Machined Parts: By modifying computer programs, it can quickly adapt to the machining needs of different parts and has extremely high flexibility.

Casting parts: The design and manufacturing of molds require a certain amount of time and cost, and for the production of small batches and multiple varieties of parts, their flexibility is relatively low.

Cost:

CNC Machined Parts: The initial investment may be high, including the purchase cost of equipment such as machine tools and programming software, but in the long run, due to high production efficiency and precision, production costs can be reduced.

Casting parts: The design and manufacturing costs of molds are relatively high, but once the mold is successfully manufactured, parts can be mass-produced to reduce the cost of individual parts.

Application field:

CNC Machined Parts: widely used in aviation, automotive, electronics, molds and other fields, especially for high-precision and high-quality parts.

Casting parts: mainly used for manufacturing large and complex metal parts, such as engine cylinder blocks, turbine blades, etc.

Therefore, there are significant differences between CNC Machined Parts and castings in processing principles, accuracy and tolerances, material adaptability, production efficiency, flexibility, cost, and application areas. When choosing which processing method to use, it is necessary to comprehensively consider factors such as specific part requirements, production conditions, and economic costs.

When we consider the manufacturing landscape, understanding the differences between CNC machined parts and castings is crucial for making informed decisions in various industries. Both methods have their unique characteristics, advantages, and limitations, and by exploring these distinctions, we can better match the production process to the specific requirements of a project.

One of the most significant differences lies in the manufacturing process itself. With CNC machined parts, we start with a solid block of raw material, such as metal, plastic, or composite. Our advanced CNC machines use computer – controlled cutting tools to remove material layer by layer, shaping the part according to the precise digital design. This subtractive manufacturing approach gives us a high degree of control over the final dimensions and surface finish. On the other hand, when producing castings, we pour molten material, typically metal alloys like aluminum, iron, or bronze, into a pre – made mold. Once the material cools and solidifies, we remove the casting from the mold. This additive – like process of casting allows for the creation of complex shapes in a single piece, especially those with internal cavities or intricate geometries that would be difficult to achieve through machining.

Precision is another area where these two methods diverge. CNC machining offers us unparalleled accuracy. We can achieve extremely tight tolerances, often within microns, making it ideal for parts that require exacting dimensions, such as components in aerospace engines or medical devices. The repeatability of CNC machines ensures that each part in a batch is identical, reducing the risk of assembly issues. Castings, while capable of good precision, generally have larger tolerances compared to CNC – machined parts. Variations in the cooling process, mold shrinkage, and other factors can lead to minor dimensional differences. However, with modern casting techniques and careful mold design, we can still produce castings with acceptable precision for many applications, like automotive engine blocks.

Material utilization also sets CNC machined parts and castings apart. In CNC machining, since we remove material to create the part, there is often a significant amount of scrap generated, especially for complex shapes. This can increase the cost of production, especially when working with expensive materials. In contrast, casting is more efficient in terms of material use. The molten material fills the mold cavity, and we can design the mold to closely match the final shape of the part, minimizing waste. This makes casting a more cost – effective option when dealing with large – scale production and materials that are difficult or expensive to machine.

The surface finish of the parts is another differentiator. CNC – machined parts typically have a smooth and consistent surface finish, which can be further enhanced through additional processes like polishing or grinding. This is beneficial for parts where aesthetics or reduced friction is important. Castings, on the other hand, may have a rougher surface texture due to the nature of the mold and the solidification process. Surface finishing operations, such as machining, shot blasting, or painting, are often required to improve the appearance and functionality of castings.

Lead times and production flexibility are also important considerations. CNC machining allows for relatively quick turnaround times, especially for small – batch production or prototyping. We can easily make design changes by modifying the digital program, enabling rapid iterations. Casting, on the other hand, involves the time – consuming process of creating molds, which can extend the lead time, especially for custom designs. However, once the mold is made, casting is highly efficient for high – volume production, as we can produce multiple parts in a short period.

In conclusion, the differences between CNC machined parts and castings are multi – faceted, encompassing manufacturing processes, precision, material utilization, surface finish, lead times, and production flexibility. By carefully evaluating these aspects, we can choose the most suitable method for each project, ensuring optimal performance, cost – effectiveness, and timely delivery.