Mechanical Properties Comparison for CNC Machined Parts

When selecting materials for CNC machined parts, understanding mechanical property differences between metals and plastics is fundamental to performance. Metals generally offer superior tensile strength, with aluminum alloys providing 200–600 MPa and steel alloys ranging from 400–1,200 MPa, making them ideal for load-bearing CNC machined parts. Plastics like ABS and nylon typically exhibit tensile strengths between 20–80 MPa, suitable for lighter-duty applications. Metals also excel in impact resistance and fatigue life, critical for CNC machined parts subjected to repeated stress, such as automotive components. Plastics, however, offer better flexibility and toughness in some cases—polycarbonate withstands significant impact without shattering, making it valuable for protective CNC machined parts. We conduct rigorous testing comparing how metal and plastic CNC machined parts perform under temperature variations, with metals maintaining strength at higher temperatures (up to 400°C for steel) versus plastics that may soften above 100–200°C. These property differences guide our recommendations, ensuring CNC machined parts meet the specific mechanical demands of their intended use.

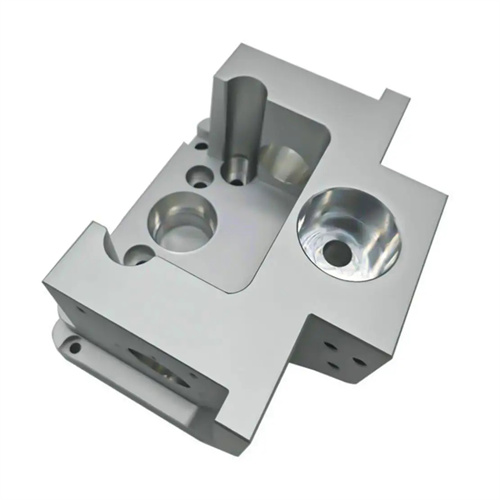

Machining Characteristics of Metals and Plastics for CNC Machined Parts

The machining behavior of metals versus plastics significantly impacts production efficiency and CNC machined parts quality. Metals require higher cutting forces and specialized tooling—carbide inserts for aluminum, high-speed steel for steel alloys—to achieve precise finishes. They produce continuous chips that require effective chip evacuation systems to prevent tool damage and maintain surface quality in CNC machined parts. Plastics, by contrast, machine with lower cutting forces and generate discontinuous chips, reducing tool wear and allowing faster feed rates. However, plastics present unique challenges like melting from friction heat, requiring controlled spindle speeds and coolant systems to prevent distortion in CNC machined parts. We adjust machining parameters dramatically between materials: aluminum alloys machine at 1,000–5,000 RPM with high feed rates, while engineering plastics require 3,000–8,000 RPM with reduced feeds to avoid thermal issues. Tool geometry also differs—sharp, high-helix tools for plastics versus stronger, more robust tooling for metals. Understanding these characteristics allows us to optimize processes for both material types, producing high-quality CNC machined parts efficiently.

Cost Analysis for Metal vs Plastic CNC Machined Parts

Cost considerations play a critical role in material selection for CNC machined parts, with metals and plastics offering different economic profiles across production stages. Raw material costs vary significantly: basic plastics like polyethylene cost \(2–5 per kilogram, while engineering plastics range from \)5–30/kg. Metals typically start higher, with aluminum at \(3–8/kg, steel at \)1–5/kg, and titanium at $30–100/kg. However, machining costs often reverse this trend—plastics require less energy and tooling wear, reducing per-part processing costs by 20–30% compared to metals for similar geometries. For low-volume CNC machined parts, plastics often provide lower total costs due to reduced machining time. High-volume production may favor metals, as their longer tool life and faster cycle times can offset higher material costs. We also factor in secondary operations: metals frequently require finishing treatments like plating or painting, adding costs absent for many plastic CNC machined parts. Our cost analysis considers the entire lifecycle, helping clients balance initial production costs against performance requirements for their CNC machined parts.

Application-Specific Selection for CNC Machined Parts

Material selection for CNC machined parts depends heavily on application requirements, with metals and plastics each excelling in specific environments. Industrial machinery relies on metal CNC machined parts for structural components, where steel’s strength and wear resistance prevent premature failure under heavy loads. Automotive applications use aluminum for lightweighting and corrosion resistance in parts like brackets and housings. Plastics dominate in consumer goods, where their lower weight, colorability, and insulation properties benefit CNC machined parts like handles and enclosures. Medical devices often use specialized plastics like PEEK for biocompatibility or stainless steel for sterilizability in critical CNC machined parts. We recommend metals for high-temperature applications—engine components operating above 150°C where plastics would degrade. Conversely, electrical insulation applications favor plastics to prevent conductivity in CNC machined parts. Our application engineers evaluate factors like environmental exposure, load requirements, and regulatory compliance to recommend optimal materials, ensuring CNC machined parts perform reliably in their specific use cases.

Design Considerations for Metal and Plastic CNC Machined Parts

Material selection influences design decisions for CNC machined parts, with metals and plastics enabling different geometric possibilities and constraints. Metal CNC machined parts accommodate thin walls down to 0.5mm for aluminum and 0.3mm for steel, withstanding higher stress concentrations than plastics. They support complex features like deep holes and internal threads without significant deflection during machining. Plastics require thicker wall sections (minimum 1mm for most materials) to prevent vibration-induced chatter during machining and ensure structural integrity in finished CNC machined parts. They also benefit from generous radii and draft angles to minimize stress points that could lead to cracking. We design metal CNC machined parts with tighter tolerances (±0.01mm achievable) compared to plastics (typically ±0.05mm due to thermal expansion). Threaded features in plastics often require metal inserts for durability, while metals can be directly threaded. Our design team collaborates with clients to optimize geometries for their chosen material, ensuring manufacturability while maximizing performance in CNC machined parts.

Future Trends in Materials for CNC Machined Parts

Emerging material technologies are expanding possibilities for CNC machined parts, blurring traditional distinctions between metals and plastics. Metal matrix composites combine metal strength with ceramic reinforcement, offering enhanced wear resistance for high-performance CNC machined parts. Advanced polymers like PEEK and PEKK bridge the gap between plastics and metals, providing strength approaching aluminum at lower weights for aerospace and medical CNC machined parts. We’re also working with hybrid materials—plastic components with metal inserts that combine insulation properties with structural strength. Sustainable options are growing in importance: recycled plastics and bio-based polymers reduce environmental impact for eco-conscious CNC machined parts, while recycled metals maintain performance with lower embodied energy. Additive manufacturing advancements allow metal-plastic hybrid structures previously impossible with conventional machining. Our materials research focuses on these innovations, testing new composites and alloys to expand the capabilities of CNC machined parts. These trends enable more tailored solutions, combining the best properties of metals and plastics for optimized performance in future CNC machined parts applications.