Material Properties for Lightweight CNC Machined Parts

Aluminum and titanium stand out as premier materials for lightweight CNC machined parts, offering exceptional strength-to-weight ratios that outperform traditional steels. Aluminum alloys like 6061 and 7075 provide a perfect balance—with densities around 2.7 g/cm³, they weigh approximately 30% of the equivalent steel component while maintaining sufficient strength for structural applications. Titanium alloys, particularly Ti-6Al-4V, take lightweighting further with a density of 4.5 g/cm³, offering 40% weight savings over steel while delivering higher strength than aluminum. We leverage these properties by selecting aluminum for non-critical structural CNC machined parts where cost efficiency matters, and titanium for high-stress components requiring both light weight and extreme durability. Both materials exhibit excellent machinability when paired with proper tooling, allowing us to create intricate geometries that maximize strength while minimizing mass. Our material testing confirms that properly designed aluminum and titanium CNC machined parts can meet or exceed the performance of heavier steel alternatives in most applications.

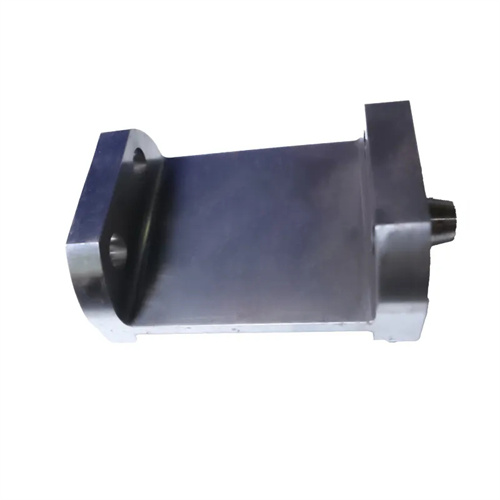

Structural Optimization for Aluminum CNC Machined Parts

Design optimization plays a critical role in maximizing lightweighting benefits in aluminum CNC machined parts. We employ advanced techniques like topology optimization, which uses algorithms to remove material from low-stress areas while maintaining structural integrity. This process creates organic, lattice-like structures in aluminum components that reduce weight by 20–40% compared to traditional designs. We also implement thin-wall machining strategies, creating walls as thin as 0.5mm in 6061 aluminum CNC machined parts without sacrificing rigidity. Ribbed designs distribute loads effectively across larger surfaces, eliminating unnecessary material in flat sections. Our engineers use finite element analysis (FEA) to simulate stress distribution, identifying opportunities to hollow out internal sections of aluminum parts while preserving strength. We also optimize part consolidation, replacing multi-component assemblies with single aluminum CNC machined parts that reduce total weight through integrated design. These structural strategies, combined with aluminum’s natural light weight, deliver significant mass reduction in finished components.

Advanced Machining Techniques for Titanium CNC Machined Parts

Titanium’s unique properties require specialized machining techniques to achieve optimal lightweight designs in CNC machined parts. We use high-speed machining centers with rigid frames and powerful spindles (15,000+ RPM) to efficiently remove material from titanium alloys, creating thin-walled features and complex geometries that maximize lightweighting. Coolant-through tooling with high-pressure systems (70+ bar) ensures effective heat dissipation, preventing work hardening that can damage tools and compromise surface finish in titanium CNC machined parts. We employ trochoidal milling strategies that reduce tool engagement time, minimizing heat buildup while allowing deeper cuts for hollowed sections. Our 5-axis machining capabilities enable undercut features and complex contours that remove excess material from titanium parts without secondary operations. We also use ultrasonic-assisted machining for intricate lightweight designs, reducing cutting forces by up to 30% and enabling thinner walls (0.3mm) in critical titanium CNC machined parts. These advanced techniques unlock titanium’s full lightweight potential while maintaining production efficiency.

Application-Specific Lightweighting for CNC Machined Parts

Aluminum and titanium CNC machined parts deliver targeted lightweighting benefits across diverse industries with unique requirements. Aerospace applications rely heavily on titanium CNC machined parts for engine components and structural elements, where each kilogram saved reduces fuel consumption significantly over an aircraft’s lifespan. Automotive manufacturers use aluminum extensively for suspension components, engine brackets, and chassis parts, achieving 30–50% weight reduction compared to steel alternatives. In robotics, aluminum CNC machined parts reduce inertia in moving components, improving energy efficiency and performance. Medical devices utilize titanium’s biocompatibility and lightweight properties for surgical instruments and implantable components where patient comfort and device maneuverability are critical. We tailor lightweighting strategies to each application: maximizing material removal in non-critical areas of aluminum CNC machined parts while preserving strength in high-stress regions, and leveraging titanium’s higher strength for thinner, lighter components in safety-critical applications. This application-specific approach ensures optimal lightweighting without compromising functionality.

Strength-to-Weight Balancing in CNC Machined Parts

Achieving the perfect strength-to-weight balance requires careful engineering of aluminum and titanium CNC machined parts. We conduct rigorous testing to determine the minimum material thickness needed for each component, using tensile testing and fatigue analysis to validate lightweight designs. For aluminum CNC machined parts, we often specify 6061 alloy for general applications requiring good strength at moderate cost, reserving higher-strength 7075 for components subjected to extreme loads. Titanium’s superior strength allows us to design thinner walls and smaller cross-sections in CNC machined parts, offsetting its higher density compared to aluminum. We use FEA to simulate real-world loading conditions, ensuring lightweight designs don’t create unintended stress concentrations. Our engineers also consider joining methods—designing aluminum and titanium CNC machined parts with integrated fastening features that eliminate heavy hardware. We validate each balanced design through physical testing, subjecting lightweighted parts to load testing, vibration analysis, and environmental exposure to ensure they meet performance requirements. This balancing process ensures our CNC machined parts achieve maximum weight reduction without sacrificing reliability.

Cost and Manufacturing Efficiency in Lightweight CNC Machined Parts

Balancing lightweighting benefits with cost efficiency is crucial when producing aluminum and titanium CNC machined parts. Aluminum offers lower material costs and faster machining speeds, making it ideal for high-volume lightweight applications where production efficiency is key. We optimize aluminum CNC machined parts for high-speed production, using standard tooling and minimizing complex features to keep costs low. Titanium’s higher material cost and slower machining rates make it more suitable for high-value, low-volume applications where extreme lightweighting justifies the expense. We maximize titanium material utilization through nesting optimization, arranging part geometries to minimize waste from expensive stock. Our programming teams develop efficient toolpaths that reduce cycle times for both materials—using high-feed strategies for aluminum and optimizing coolant delivery for titanium CNC machined parts. We also evaluate total cost of ownership, considering that lightweight aluminum and titanium parts often reduce downstream costs through improved energy efficiency or extended product lifespan. By balancing material selection, design complexity, and production methods, we deliver cost-effective lightweight CNC machined parts that meet performance and budget requirements.